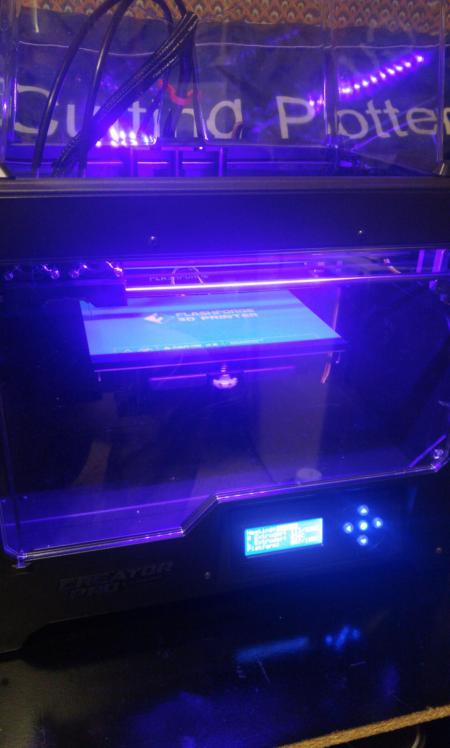

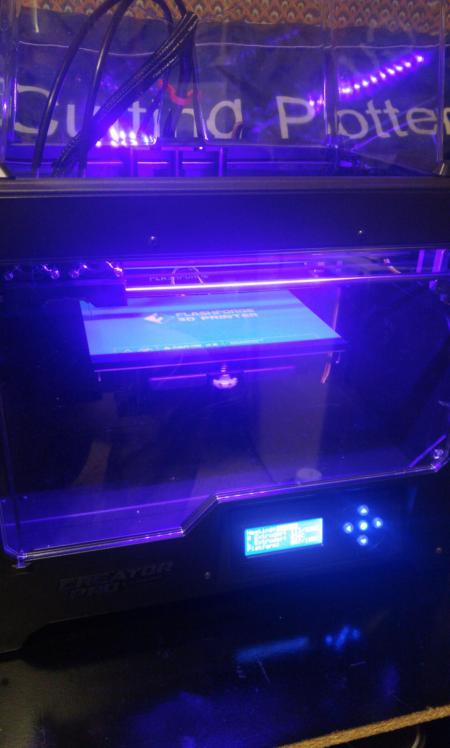

This may be initially one of the coolest 3D Printers we have come across. It boasts an enclosure, which is very important when printing hotter materials outside of PLA filaments. It has two extruders, allowing you to mix and match colors as well as different filaments.

Aside from installing a borosilicate glass bed, this is the first upgrade we had our eyes on for the printer. It is lighter, and more robust in design. This was created by an adept user and enables you to print at higher speeds. Aside from faster movement, it is actually designed much better than the original carriage. This allows for faster and less painful disassembly which is required for jams in your hotend. This piece has shrunk a 1-2 hour downtime to half an hour.

This glass is different from ordinary glass. While it is not necessarily better than ordinary glass surface custom cut from your local hardware store, or even a glass mirror, it is the most heat resistant glass. Although it is probably the smoothest glass, this actually makes more problems when it comes to 3D printing. Your first layers will not always stick to borosilicate, and when printing at higher temperature filaments, it may be completely stuck to your glass. Getting it off is always a pain, but it may also chip your borosilicate glass and your 3D printed part will then have a unsmooth bottom with glass on it. Some of the other cons are it takes longer to heat. This glass is effectively an even larger heatsink for your heated bed, and maybe require you to actually bump up your temperature before starting your print to get the desired temperature.

The best results I have gotten are with the stock FlashForge stickers for the heated bed. It is essentially very thick sandpaper with a nice and sticky 3M adhesive on the other side. Aside from requiring scrubbing the heated bed after removal, it is probably the best surface I have printed on and many other companies have developed products to match this surface, such as BuildTak. I have had prints that has been very difficult to remove from this surface, and if you are not careful you can gouge your sandpaper surface and rip a hole. You would think these holes would pose more issues, but I have actually printed successfully over these holes, or cuts on the surface.

This may be initially one of the coolest 3D Printers we have come across. It boasts an enclosure, which is very important when printing hotter materials outside of PLA filaments. It has two extruders, allowing you to mix and match colors as well as different filaments.

This may be initially one of the coolest 3D Printers we have come across. It boasts an enclosure, which is very important when printing hotter materials outside of PLA filaments. It has two extruders, allowing you to mix and match colors as well as different filaments.