| A brief discussion of geometric dimensioning

and tolerancing practices.

The practice of

geometric dimensioning and tolerancing is a scientific tool intended to reduce design,

manufacturing and inspection risk. Specifically, GD & T is a symbolic language for unambiguously

specifying functional limits of the amount of imperfection in geometry. Since there is

no such thing as a "perfect" part, a method must be in place so that the designers, manufacturers

and inspectors of the part are "all on the same page". GD & T, as it applies to metrology, allows

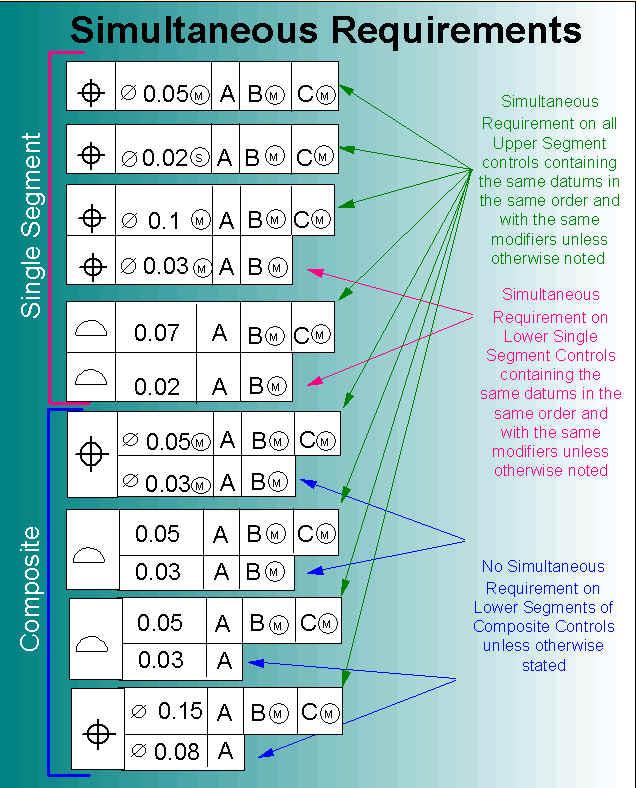

the functional product quality to be assessed. The language of GD & T involves the use

of special symbols as seen at the left.

The practice of

geometric dimensioning and tolerancing is a scientific tool intended to reduce design,

manufacturing and inspection risk. Specifically, GD & T is a symbolic language for unambiguously

specifying functional limits of the amount of imperfection in geometry. Since there is

no such thing as a "perfect" part, a method must be in place so that the designers, manufacturers

and inspectors of the part are "all on the same page". GD & T, as it applies to metrology, allows

the functional product quality to be assessed. The language of GD & T involves the use

of special symbols as seen at the left. These symbols define a "datum structure" which spells out

the relationship between actual features (geometric elements such as planes, lines, circles and

points) and their mathematical counterpart--the only way a Coordinate Measuring Machine (CMM) can

deal with them. The intent in manufacturing, as well as inspection, is to limit the so-called

degrees of freedom that a part has. For example, a book is free to move about in space unless

constrained in some way (such as setting it on a table). When the book is resting on the table,

it cannot move up or down (that is, it is constrained in the "Z" direction). There are six degrees

of freedom: translation in X, Y and Z, as well as rotation about the X, Y or Z axes (some authors

refer to rotational degrees of freedom as roll, pitch and yaw). When manufacturing a part, all six

degrees of freedom must be fixed--or else the part will fly off the machine! In the same way, the

part's movement must be fixed when measuring on a CMM. These symbols define a "datum structure" which spells out

the relationship between actual features (geometric elements such as planes, lines, circles and

points) and their mathematical counterpart--the only way a Coordinate Measuring Machine (CMM) can

deal with them. The intent in manufacturing, as well as inspection, is to limit the so-called

degrees of freedom that a part has. For example, a book is free to move about in space unless

constrained in some way (such as setting it on a table). When the book is resting on the table,

it cannot move up or down (that is, it is constrained in the "Z" direction). There are six degrees

of freedom: translation in X, Y and Z, as well as rotation about the X, Y or Z axes (some authors

refer to rotational degrees of freedom as roll, pitch and yaw). When manufacturing a part, all six

degrees of freedom must be fixed--or else the part will fly off the machine! In the same way, the

part's movement must be fixed when measuring on a CMM.

|